Rock-Eval reservoir mode

Application

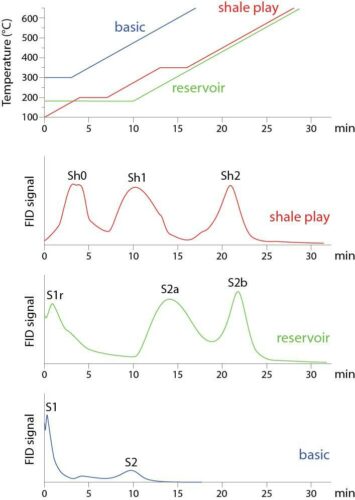

Rock-Eval pyrolysis can be used to screen for the presence of migrated hydrocarbons in suspected reservoir intervals. Although standard Rock-Eval analysis, as used for source rocks, can be used, more information is potentially available via operation in the reservoir mode. During the thermal desorption step the free oil content, equivalent to the S1 measurement from standard mode, is represented by the S1r and S2a peaks.

During the pyrolysis phase the S2b peak represents cracking of resins and asphaltenes, and provides a way to identify tar mats. Non-pyrolysable material, which is combusted at the end of the process, represents pyrobitumen.

The HAWK instrument at APT also has a reservoir mode

Parameters from Rock-Eval analysis in reservoir mode

Value added by APT analysis

| Parameter | Definition | Measurement | Application |

|---|---|---|---|

| S1r | light volatisable oil | wt‰ HC/rock | free bitumen |

| S2a | heavy volatilisable oil | wt‰ HC/rock | richness/quality |

| S2b | pyrolysable NSO fraction | wt‰ HC/rock | tar mat identification |

| RC | residual, non-pyrolysable C | wt% C/rock | pyrobitumen content |

Sample requirements

Finely milled rock samples are required. They can be cuttings, chips or plugs from core or side-wall core. In the case of cuttings, the 1−4 mm size fraction should preferably be used, and picking of selected lithologies may be required. Sampling frequency should aim to capture variations across potential barriers suggested by well logs.

Washed and dried samples are crushed and milled. 20−30 g of unwashed cuttings, or 2−3 g of washed cuttings or core material normally suffices for TOC and Rock-Eval analyses, although a minimum of ~0.5 g of washed material may be adequate if limited sample is available.

It may also be beneficial, on the basis of the Rock-Eval screening, to select a sub-set of samples for more detailed analysis of extracts by GC and GC-MS. Sample amounts should be collected with this possibility in mind.

Although washing may not remove all traces of organic mud components, which contribute to TOC and adversely influence Rock-Eval measurements, further treatment is not advisable in reservoir studies because of the potential removal of migrated oil along with contaminants.

Analytical procedure

During a typical Rock-Eval analysis the powdered sample of rock is initially heated at 180°C in an inert atmosphere (He) for 10°/min in order to liberate the free light hydrocarbons (C1–C15), yielding the S1r measurement via a flame ionisation detector (FID). The temperature is then increased at 25°/min to 650°C to liberate, initially, the C15–C40 oil components as the S2a peak, again quantified by the FID.

Pyrolysable material is then generated as the S2b measurement towards the end of the heating cycle, broadly equivalent to the traditional S2. The non-pyrolysable material is then combusted to determine residual carbon (RC), via carbon dioxide measured as the S4 parameter using a thermal conductivity detector (TCD).

Whereas the range of S1 and S2 parameters are recorded as wt‰ of rock, RC is presented as wt%, and the amount of hydrocarbons, as wt‰ of rock, it represents is calculated as 10*RC/0.9. The corresponding amount of NSO compounds (i.e. asphaltenes plus resins) is represented by S2b = (10*RC/0.9) wt‰ of rock. Tmax is recorded as the maximum of the S2b peak.

On the HAWK instrument, the corresponding temperature programme is 10 min at 180°C, to yield the equivalent S1r measurement, followed by 10°/min to 650°C, plus 1 min at the top temperature, liberating the heavier and pyrolysable hydrocarbons.

Potential problems

The presence of organic-additives in drilling mud can adversely affect both TOC and Rock-Eval data. Although washing can remove the bulk of the additives, it is not uncommon for residues of varying proportions to remain in some samples, so caution should be exercised during interpretation.

Although TOC is likely to be affected to an extent, although the greatest influence of mud residues is usually observed in Rock-Eval results. Oil-based mud (OBM) generally augments the S1 measurement, but polymeric organic material based on glycol and similar additives is less volatile and tends to produce a precursor to the S2 peak. If sufficiently great, this precursor becomes indistinguishable from the genuine S2 signal and a single broad peak results, with a depressed Tmax value.

Inspection of pyrograms is therefore always recommended. Oxygen-containing organic mud additives such as polyglycols also contribute to the S3 signal, so abnormally high OI values can result.

If oil or other organic mud additives are known to have been used, this contamination of source rocks is best removed by solvent extraction prior to the TOC and Rock-Eval analyses, so that more reliable TOC, S2, S3, HI, OI and Tmax values can be obtained. The S1, PI and PP values will be of no use because any indigenous bitumen or migrated hydrocarbons will be removed together with the OBM contaminant. This is not too detrimental where the prime purpose is to evaluate kerogen quality, but clearly cannot be performed for reservoir analysis.

Coring and core plugging can involve the use of oil-based lubricants. Whereas nothing can be done about coring procedures during exploration, samples are best taken away from core margins or the sites of core plugging to minimize potential contamination. Core plugs for the purposes of organic geochemical analysis should be drilled using water as a lubricant (but not if the purpose is inorganic analysis of reservoir sections, such as Sr isotope RSA).

Cavings can be problematic for cuttings, particularly if insufficient of what is believed to be the indigenous lithology can be picked. Worn conventional bits can produce mostly flour, which is difficult to recover during washing and cannot be picked effectively.

Turbo-drilling can result in localised heating to the extent that the resulting fine cuttings exhibit signs of artificial maturation in data obtained from organic analyses. Casing and bit change depths can aid identification of problem intervals.

References

Trabelsi K., Espitalié J., Huc A.Y. (1994) Characterisation of extra heavy oils and tar deposits by modified pyrolysis methods. Proceedings of the ‘Heavy Oil Technologies in a Wider Europe’ Thermie EC Symposium, Berlin, 30–40.

Peters K.E. (1986) Guidelines for evaluating petroleum source rock using programmed pyrolysis. AAPG Bulletin 70, 318−329.