Maximising the value of geochemical data: drilling fluids and base oil contamination

By: Ian Cutler & Patrick Barnard (APT UK)

The negative effects of drilling additives on the geochemical analysis of downhole samples are well documented. APT work closely with their clients during well planning to assist in clearly identifying what the geochemical work programme should achieve. This has been shown to greatly improve the results obtained, as the work programme can be tailored to maximise outcomes. Should forward planning not be possible, APT have developed several remediation methods to help overcome these issues and ensure our clients get the best possible results.

Rock samples (cuttings, sidewall cores and cores) and down hole fluids (DST, MDT mud gases) are acquired using drilling fluids (water or more commonly presently oil-water emulsion-based systems - OBM) which can introduce contamination to the samples. The use of OBM is often routine, either for cost reasons or due to specific geological conditions and problems. However, such muds contaminate cuttings and, to a greater or lesser extent SWC, core, and bottom hole fluid samplers such as MDT, RCI etc.

The extent of the contamination in rocks tends to be greater in i) smaller sample sizes – so very fine cuttings tend to be more contaminated than conventional core and ii) more porous samples such as sand. Extent of contamination in bottom hole samples depends on multiple factors such as hydrocarbon fluid type, pump-out time, formation poro-perm etc.

Geochemists at APT are well accustomed to these issues and have developed a number of remediation methods to overcome these problems.

Problems with OBM - base oil

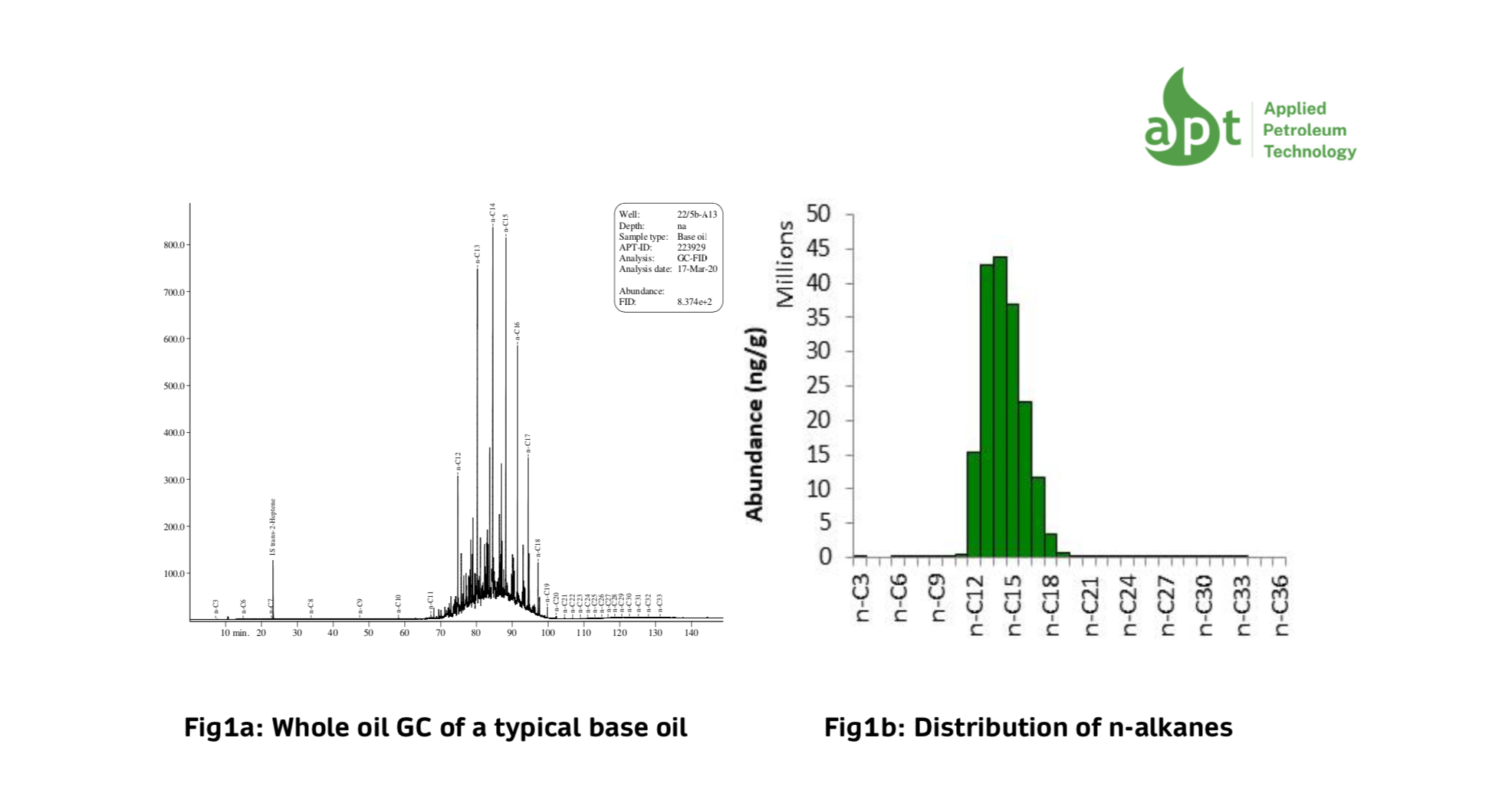

One type of OBM consists of base oils with very tight distillation cuts. A typical example is shown in Fig. 1 with a from n-C12 to n-C18 with few lighter components and essentially no heavier components. Contamination of this nature causes problems for the geochemist, but the effects are restricted to a narrow range of compounds and useful data can still be acquired for compounds outside this carbon number range.

Some base oils consist mainly of n-alkenes (olefins) which are not even present in oils, and these cause even fewer potential problems unless present in very high amounts. Other types of base oil, such as diesel, may cause greater problems as they cover a wider carbon number range, and may also include aromatic compounds not found in many synthetic base oils.

However, the drilling fluid is not composed solely of base oil. Whilst the amounts of components in the base oil outside the narrow cut are small, and other additives or contaminants may cause problems. For example, biomarkers may be present if the mud has been recycled. Alternatively, solids such as lignite, not seen in an analysis of the base oil, may impact TOC or pyrolysis data.

Mitigation – Oil based muds

Well planning

A geochemist would love to say “just use water-based mud” – although complications can exist with WBMs particularly when polyglycol additives are used to stabilise the clays, but these are usually orders of magnitude less problematic. But this isn’t realistic, so what can be done to minimise problems from OBMS?

Recognition

- The key to mitigating contamination is recognising its presence and understanding its source.

- A well programme planned with geochemistry in mind should forewarn the geochemical contractor of likely difficulties and provide the maximum amount of up- front information possible.

Thinking ahead

- Clearly identifying what the geochemical work programme should achieve through discussion with the contractor prior to commencement will greatly aid the result obtained.

For example, a study aimed at characterising recognised oil stains will follow a different process to one aimed at confirming the presence or otherwise of marginal stains.

- With all this information, the contractor can tailor a work programme that will maximise outcomes.

Understand what is in the mud

A full list of all compounds used to formulate the mud throughout the drilling programme should be collected and provided.

This should include additives added specifically to mitigate short lived well problems, e.g. extra lubricant additives to cope with a stuck pipe.

Obtain and provide to the laboratory samples of each chemical used, particularly the organic based ones.

It may not be necessary to analyse these, but they can be held in reserve to study if additional information could resolve ambiguous results.

Sample and analyse muds

- Best outcomes will be obtained if several mud samples are collected and analysed for comparison with each other and the data obtained from the rocks and fluids.

- The number of mud analyses undertaken will depend on the impact of the mud and the criticality of the geochemical results.

- Consider collecting some or all of the following mud samples:

- Sample of the base oil used to formulate the mud and all organic materials used

to make up the mud. (Allows characterisation of any mineral oil components that might contaminate the rock and oil samples.) - A sample of the re-used make up mud from previous drilling operations. (Allows assessment of hydrocarbons which may have been introduced from previous drilling operations.)

- Samples of formulated mud prior to circulation.(Allows assessment of compounds introduced into the system by the mud as a whole and unaffected by compounds collected during the drilling.)

- Samples of muds circulated over the interval of interest (reservoir, source rock interval). (Allows an assessment of what is in the mud during a critical drilling stage, can be directly compared to the data from the geological samples and evaluate if the mud itself is affected by the rocks being drilled.)

- Samples of mud from sections above the intervals of interest which are unlikely to contain either source rocks or migrant fluids.

(These provide control on the mud data against which the mud from the interval of interest can be assessed.) - A mud sample any time either anything is changed in the drilling fluid composition, or there is a drilling event, such as a casing point, a trip etc.

- Sample of the base oil used to formulate the mud and all organic materials used