Well sampling

Rock Samples

For geochemical purposes, conventional core chips/plugs, side wall cores and ditch cuttings are suitable for analysis. The types of samples and frequency of the sampling will depend upon several factors, such as the type/purpose of the well (wildcat in frontier or mature areas, appraisal well etc.) and budget.

Please contact us to get details on the amounts of sample required for various types of geochemical analysis.

Ditch cuttings

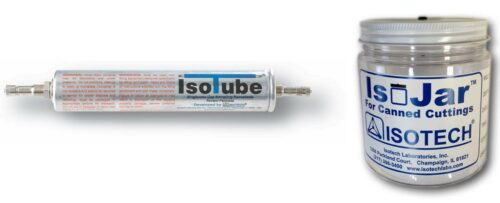

Ditch cuttings for geochemical analysis are routinely collected as either ‘washed and dried’ or unwashed samples in bags. However, if any headspace/cuttings gas analysis has been performed, the residual cuttings (from uncoated cans or Isojars) can be used, although they may contain bactericide to inhibit biodegradation of gaseous hydrocarbons during storage.

Brine is a common bactericide, and it causes corrosion of cans, which may to lead to leakage/perforation and consequent degradation of the gas sample after 6 months or so. If long-term storage of ditch-cutting gas is required, Isojars are recommended.

For a wildcat well drilled in a frontier or poorly explored area with unknown source rock(s) and reservoir sections, the sampling frequency of ditch cuttings should be high, preferably up to every 3 m throughout the well. This allows a thorough analysis of the well and identification of any source or reservoir sections, which will be crucial for basin modelling.

For wildcat wells in mature basins the sampling strategy can be based on prior knowledge of drilled wells, and generally can be less frequent within zones of little stratigraphic interest. For example, sampling may be sufficient at 10 m intervals in reservoir overburden and at 5 or 3 m intervals in any anticipated source rock horizons and/or reservoir zones.

Recommended sampling interval for ditch cuttings

| Ditch cutting sampling interval | Wildcat wells in frontier areas | Wildcat wells in explored areas | Wildcat wells in mature areas | Appraisal wells |

|---|---|---|---|---|

overburden (above source or reservoir) |

3 m |

5 m |

10 m |

10–20 m |

source rocks section |

3 m |

3 m |

3 m |

3 m |

reservoir section |

3 m |

3 m |

3 m |

3 m |

below reservoir/ source rock |

3 m |

3 m |

5–10 m |

5–10 m |

Unwashed cuttings require careful washing, and previously washed samples may not be adequately free of drilling mud, so should be inspected for the need for further washing.

Sample selection should be based on logs and cuttings/core descriptions, which can permit intervals likely to be most heavily contaminated by cavings to be identified. However, visual inspection of the washed and dried samples to hand is always recommended, with a view to the possible need for picking representative lithologies.

Where not all of a washed sample is to be used for a set of analyses, a subsample should be taken using a proprietary sample splitter, to avoid any grain size/density bias.

Side-wall cores (SWCs)

Side-wall cores (SWCs) are usually very well suited for geochemical analysis due to good depth control and absence of contamination by cavings. SWCs are normally also less contaminated by oil or glycol based drilling muds than ditch cuttings (although drilling fluids can penetrate a considerable distance into the more porous lithologies, most notably in reservoir horizons).

However, there have been occasions when SWC samples recovered by pressure gun (rather than drilling) have actually had more OBM/glycol mud forced into them under pressure than is present in cuttings from equivalent depths. It is, therefore, advised that consideration is given to the method of SWC retrieval at the planning stage if samples ear-marked for biostratigraphic purposes may also be used for geochemical analysis.

In particular, SWCs recovered from known or expected source rock sections will be useful for evaluating variations in source potential and for mass balance calculations. Similarly, when available, SWCs at ~100 m intervals throughout a well are extremely useful for thermal maturity (vitrinite reflectance) measurements, avoiding the problems associated with cavings in ditch cuttings. The combination of source rock quality and maturity profiling based on SWCs improves the reliability of basin modelling.

Conventional cores

The amount of conventional coring of a well will depends on several factors, such as well type and location (exploration well or appraisal; frontier or mature area), drilling results, company strategy and budget. Similarly, geochemical sampling of conventional cores will be a function of the study objectives.

Typical objectives that would benefit from the analysis of core samples include detailed source rock analysis and, particularly, reservoir characterization. Whereas for some analyses (such as source rock evaluation) core chips are perfectly adequate, some reservoir analyses require clean core plugs, and the reader is referred to the reservoir section of this guide.

Sampling density will depend upon the study objectives. For source rock characterisation, representative samples should be selected throughout the section of interest, and in frontier areas (where source rock information is sparse) sampling can be as dense as 1 sample per m, whereas core sampling in wells in mature areas could be restricted to a few representative samples.

For reservoir hydrocarbon characterisation, representative samples should be collected throughout the relevant part of the cores and particularly directly over and under any lithological changes or apparently low porosity zones that may act as barriers to fluid flow and create reservoir compartmentalization.

If the objective of the study is to identify key stratigraphic changes such as OWCs, migration barriers and reservoir segregation, sampling at a minimum of metre intervals throughout the reservoir is recommended.

Potential problems

As noted above, drilling mud contamination is a general problem, but particularly so for cuttings and also for core samples from the most porous reservoir intervals. Cuttings can suffer from several other problems:

- cavings

- lack of sample due to lost returns

- need for depth correction to correlate with electric logs

- mixed lithologies due to depth range sampled during drilling

- loss of bulk of sample during washing due to fine milling by worn bit

- local metamorphism caused by worn turbo drill bit

Cores and SWCs can exhibit additional problems associated with the use of oil-based lubricants during their drilling.

Gas samples

Headspace samples

The choices about headspace gas sampling are made well in advance of drilling, so post-drilling the only decisions are which samples to analyse and by what techniques (molecular and isotopic compositions). The sealed cans contain some water in addition to cuttings.

Mud-gas samples

Mud-gas samples are collected on a routine basis by most operating companies for the purpose of examining gas accumulation in the overburden, gas leakage from the reservoir and determining the yield and composition of gas in the reservoir.

Mud-gas samples are normally collected alongside ditch cuttings for headspace/cutting gas analysis. Headspace samples are collected in cans/Isojars, whereas mud gas is typically sampled either in special aluminium bags with valve closures or in IsoTubes®.

IsoTubes, available from Isotech laboratories (http://www.isotechlabs.com), have recently become the industry standard due to their rigidity compared to gas bags, making them less susceptible to leakage. Long-term testing by the manufacturer shows virtually no chemical or isotopic degradation of gases stored for >3 yr. Furthermore, the IsoTube technology allows easy and fast shipping to the laboratory (samples can be legally shipped on both passenger and cargo aircraft according to IATA regulations), as well as easy laboratory handling.

Test samples

Gas samples from various well tests (DST, MDT, RFT) are typically collected in pressurised cylinders of various shapes and sizes. For the purpose of geochemical analysis most types of pressurized cylinders are suitable, as long as they are fitted with a proper valve allowing safe storage and subsampling.

However, for practical reasons (sufficient amount of gas, ease of handling, storage safety, transport regulations etc) small to medium sized cylinders (10–20 cm long x 5–10 cm diam.) at low pressure are recommended. High-pressure gas cylinders fall under the term ‘dangerous goods’ (ADR) and require special transport conditions.

Transport of pressurised gas should be handled by certified agents such as ‘Dangerous Goods Managements’ (http://www.dgmsupport.com). In the laboratory, gas cylinders, IsoTubes and aluminium gas bags can be stored under ambient conditions in designated places as required by HSE regulations.

Information on sending samples to APT is found here.

Once the more routine gas composition analyses have been completed, selected samples can be resampled for isotopic analysis, as required. Test gases are extremely valuable for characterising reservoir content and determining how representative are mud and headspace gas from the reservoir interval.

See the APT Girasol page for more information on the use of gas log data.

Potential problems

Test gas samples are generally not problematical, unless there has been leakage from the cylinder or problems during testing that may have led to molecular fractionation. Samples from PVT testing may no longer be representative of the original gas.

Mud and headspace gas can exhibit complementary characteristics, so analysis of both types can be informative. For example, headspace gas may appear wetter than mud gas due to preferential diffuse loss of methane from headspace cuttings during sampling. Leakage from cans can occur, but is usually obvious from hydrocarbon yields and gas wetness (some isotopic fractionation of methane may also occur).

Oil samples

Oil (and condensate) samples from well tests are typically collected in aluminium or glass flasks of various sizes. For the purpose of geochemical analysis, small glass bottles (5–20 mL) will normally be adequate, although slightly larger bottles (50–100 mL, or even greater capacity) may be required for physical test analysis (viscosity, pour point, wax content etc).

Transport to the laboratory must comply with international ADR regulations, but small amounts of oils (10–20 mL) can be shipped as air freight. Nevertheless, correct documentation is required, which is best handled by certified agents such as ‘Dangerous Goods Managements’ (http://www.dgmsupport.com), DHL, TNT or FedEX.

Oil samples in sealed glass (or aluminium) bottles can be stored in the laboratory in fridges in order to minimize alteration. In the absence of moisture and light, degradation should be minimal over many years of storage. Before long-term storage is considered, any residual aqueous phase should be removed (freezing and decanting the liquid hydrocarbons is a convenient method).

Test samples are the cleanest and most representative examples of migrated oil from an exploration well and all should be considered for geochemical characterization.

Potential problems

Samples used for other purposes, such as PVT analysis, may not be entirely compositionally representative of the original oil. It is also important to distinguish whether liquid samples represent oils or condensates, as interpretation of compositional variations can be affected.

Mud samples

Sampling and analysis of drilling mud, in particular when oil or other organic bases/additives (e.g. glycols) are present, should be mandatory.

Mud samples should, as a minimum, include the following:

- sample prior to first usage in well

- samples from immediately above and below reservoir

- samples from immediately above and below casing points

- sample from basal part of well

They should be subjected to the same geochemical analysis program as tested liquids and source/reservoir rock extracts, to evaluate the influence of contamination on the data obtained.

Potential problems

It is possible that hydrocarbons are present within the mud system, even if not oil based. Hydrocarbons may have been entrained during drilling of the well in question, or from previous usage in other wells and/or by compositional variation of hydrocarbons.

In addition, the composition of the hydrocarbons in mud may vary due to the use of different batches and/or varying degrees of incorporation of indigenous hydrocarbons in the current well. The degree of mud contamination of rock samples also varies.

Consequently, it is important to be able to distinguish indigenous hydrocarbons from mud contaminants in the intervals of interest.