Fluorescence scanning

Application

Fluorescence scanning allows for rapid, non-destructive, qualitative and quantitative logging of petroleum shows in conventionally slabbed drill cores or cuttings. Steady state fluorescence spectroscopy is used to determine the ubiquitous polycyclic aromatic hydrocarbon (PAH) content of oil. Because of the high boiling points of PAHs, they reside in cores for decades and so air exposure is not critical.

Core scanner

The HCS™ has been developed and patented by IFE (Kihle & Throndsen 1996), and employs novel HCS LabView™ software.

Coherent monochromatic light at a wavelength of 365 nm (excitation) is projected onto a 8 mm spot on a slabbed core using sapphire fiber optics; the surface being gently “kissed” by a rubber-lipped pneumatic probe head.

This causes any sorbed hydrocarbons to fluoresce, or emit photons at longer wavelengths (emission) in the UV, visible or NIR ranges (380–750 nm). The emission signal is directed through a quartz fibre, by means of a high resolution spectrometer, onto a cooled single photon counting CCD detector, and is recorded in the form of depth logs of absolute intensity and spectral distribution. A state-of-the-art fluorescence UV-intensified back-stripped ICCP detector is also available.

Representative quantitative and qualitative core depth logs are generated by the HCS™ allowing identification of commercially exploitable petroleum accumulations, together with an overall assessment of composition, from condensate to asphaltene-rich oil. In combination, the quality and quantity logs can identify potential fluid barriers and compartmentalization, as well as GOCs and OWCs.

Two types of depth log are generated:

1. Imax (max intensity, photon counts per sec) corresponds to the amount of hydrocarbons in the core. Low amounts of hydrocarbons (~500 ppm HC) correspond to relatively low photon counts (Imax 1000–1500), whereas oil legs normally yield 15000–50000 counts. The detection limit of hydrocarbons corresponds to an Imax of ~800 counts. Some lithologies (e.g. coals) may have very low background fluorescence with Imax close to zero. In order to discriminate more easily between very low counts close to zero, and sections where cores are missing (e.g. due to seal-peel) the Intensity axis (Imax) on the logs always starts at –1000 counts.

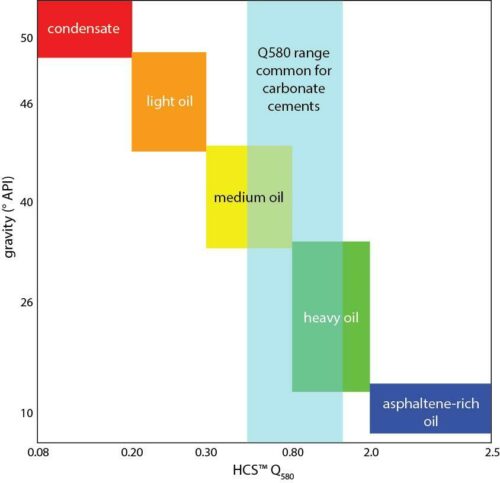

2. Q580 (fluorescence emission area quotient) is very sensitive to changes in overall petroleum composition. The higher the Q580

value, the heavier petroleum (e.g. Q580 values <0.1 = condensate, <0.25 = light oil, 0.8 ≈ 15–25° API oil and >2.0 = asphaltene rich composition). The HCSTM software has a lower Imax threshold of 800 counts for estimation of the Q580 factor (which is set to exclude measurements below the detection limit of hydrocarbons).

Cuttings scanner

A cuttings scanner (CUSC) can perform a similar evaluation of cuttings to the above core scanner, although not with such precision. Washed and dried samples are required.

The two types of depth logs differ slightly from those for the HCSTM:

1. Low amounts of hydrocarbons (~100 ppm HC) correspond to relatively low photon counts (Imax 1000–1500), whereas oil legs normally yield 15000–50000 counts. The detection limit of hydrocarbons corresponds to an Imax of ~1000 counts.

2. Q580 values <0.06 = condensate, <0.12 = light oil, 0.4 ≈ 15–25° API oil and >0.6 = asphaltene rich composition). The CUSC software has a lower Imax threshold of 1000 counts for estimation of the Q580 factor.

Potential problems

In addition to hydrocarbon fluorescence, the HCS™ logs may include interference from fluorescing mineral cements (i.e. carbonates) or drilling mud contaminants.

Carbonates

Minerals do not normally fluorescence, and the lower software threshold of 800 counts automatically excludes post-processing of measurements due to any low mineral background fluorescence. The only significant exception is carbonates, which may occur as both non-fluorescent and fluorescent types. Any carbonate fluorescence is always within the visible part of the spectrum, whereas hydrocarbon fluorescence may be invisible to the human eye; condensates commonly fluoresce in the UV range and asphaltenes in the NIR.

Carbonates may show considerable variation in both fluorescence intensity and colour. It is therefore of great importance that the operator is able to identify carbonate zones in the cores. There is usually sufficient difference in fluorescence character of hydrocarbon and carbonates in a particular core segment to allow the hydrocarbon log to be corrected for carbonate interference. The intervals where carbonate interference is important is indicated in logs (magenta colour).

Carbonates may be identified in the data set by:

- spectroscopy by their restricted Q580 signatures;

- visual identification of carbonate cementation;

- UV visual inspection – at the fringes of carbonate cementation (i.e. where cementation progress starts or where cementation is not well developed) single grains and small clusters of carbonate fluoresce as minute whitish specks against a dark background when the HCS™ probe head is placed some 5–10 mm from the core surface;

- surface texture – the core surface appearance and feel can reveal whether sandstone is densely carbonate cemented (smooth to stroke by finger-tip in contrast to the rough feel of non-cemented surfaces).

Core used for water analysis

Fluids used for sampling cores as part of water analysis (e.g. water saturation) can cause PAH contamination. Core plugs (normally one per 15–30 cm of core) are commonly drilled using a low-PAH base oil. However, in some cases the PAH-content of the drilling fluid is high and may partly or wholly mask the fluorescence signal from in-situ petroleum.

Hence, great care must be taken when evaluating the impact of any artificial additive to the core’s fluorescence behaviour.

Oil based drilling mud

Potential interference from oil based mud (OBM) is commonly limited to low Imax counts rarely exceeding 2000, with Q580 between 0.25 and 0.37.

References

Kihle J., Throndsen T. (1996a) A core scanner for continuous non-destructive hydrocarbon qualification and quantification. Abstract. 5th Norwegian meeting in Organic Geochemistry, Bergen, October 1996.

Kihle & Throndsen (1996b) EPO Patent EP0692709, Device for detecting and analyzing residual oil in coring samples and use of such device.